- #Parallel port cnc control algorithm c how to#

- #Parallel port cnc control algorithm c drivers#

- #Parallel port cnc control algorithm c driver#

- #Parallel port cnc control algorithm c software#

- #Parallel port cnc control algorithm c code#

When we have already a CNC machine and want to be able to use it as a 3D printer like RepRap, we just need to add the plastic extruder and his controller to the CNC.

Sam Wong on 2009 - (Sam blog message). #Parallel port cnc control algorithm c code#

Casainho follow the code from Sam Wong (with much of his help), on 2009. There are at least 4 users that already made an EMCRepStrap and documented and shared their code: If you want to be able to print with the best technology available, RepRap Mendel is by far the best technology and investment you can do, because it is used by everyone and all developments happens there. #Parallel port cnc control algorithm c software#

Please note that the current hardware, firmware and software needed to run EMCRepStrap is not used by many people (maybe just 3 users?, with his own forks) and so it's not very well tested and documented.

See here an old video that shows EMC2 printing (registed by Casainho on 2009.11.09). If you have a CNC machine which you control using EMC2 on GNU/Linux, you can just mount the plastic extruder and start printing using EMC2.

Uses the official Arduino-based extruder electronics and (thus far) the official Arduino firmware. (Calls Skeinforge to process the GTS into G Code printing instructions.) axis_gts_handler.py : A Python application configured as an Axis FILTER which allows a GTS file to be opened directly from Axis. Has the various bits of configuration needed to pull all the above parts together.  EMC ini File : More of a sample really.

EMC ini File : More of a sample really. #Parallel port cnc control algorithm c driver#

HAL config files : Define the 'wiring' of the signals and ports defined by the User-Space HAL Driver and the VCP. pyVCP : A virtual control panel providing a GUI for the extruder. User-Space HAL Driver : Python application which provides status from the extruder back to EMC/Axis. M-Apps : Small applications that EMC calls when it encounters a custom M-Code. Riding on the G-Code based tool-chains being developed this project provides some relatively simple "glue" applications and configurations which are intended to make it easy to bolt an extruder to an existing CNC mill or router and start printing. If you've gotten this to work, *please* tell us how. Alas, as far as I know, no one has successfully made good parts with this approach (c). #Parallel port cnc control algorithm c how to#

A few small steps have been made in this direction (see "Emc2Arduino", "RepRap forums: How to establish a connection EMC2 with RepRap ?" and "Arduino in EMC" giving a board with 6 * 10-bit analog inputs 6 * 8-bit PWM "analog" outputs 6 digital inputs/outputs). This approach allows us to run EMC on laptops that don't have a parallel port, and use it to not only drive a RepRap but a variety of other CNC machines - a very useful capability. But instead of using the standard "RepRap Host Software" (does this have a better name?) or RepSnapper as in a standard RepRap CAM Toolchains, instead we use EMC to control everything through a single USB cable.

#Parallel port cnc control algorithm c drivers#

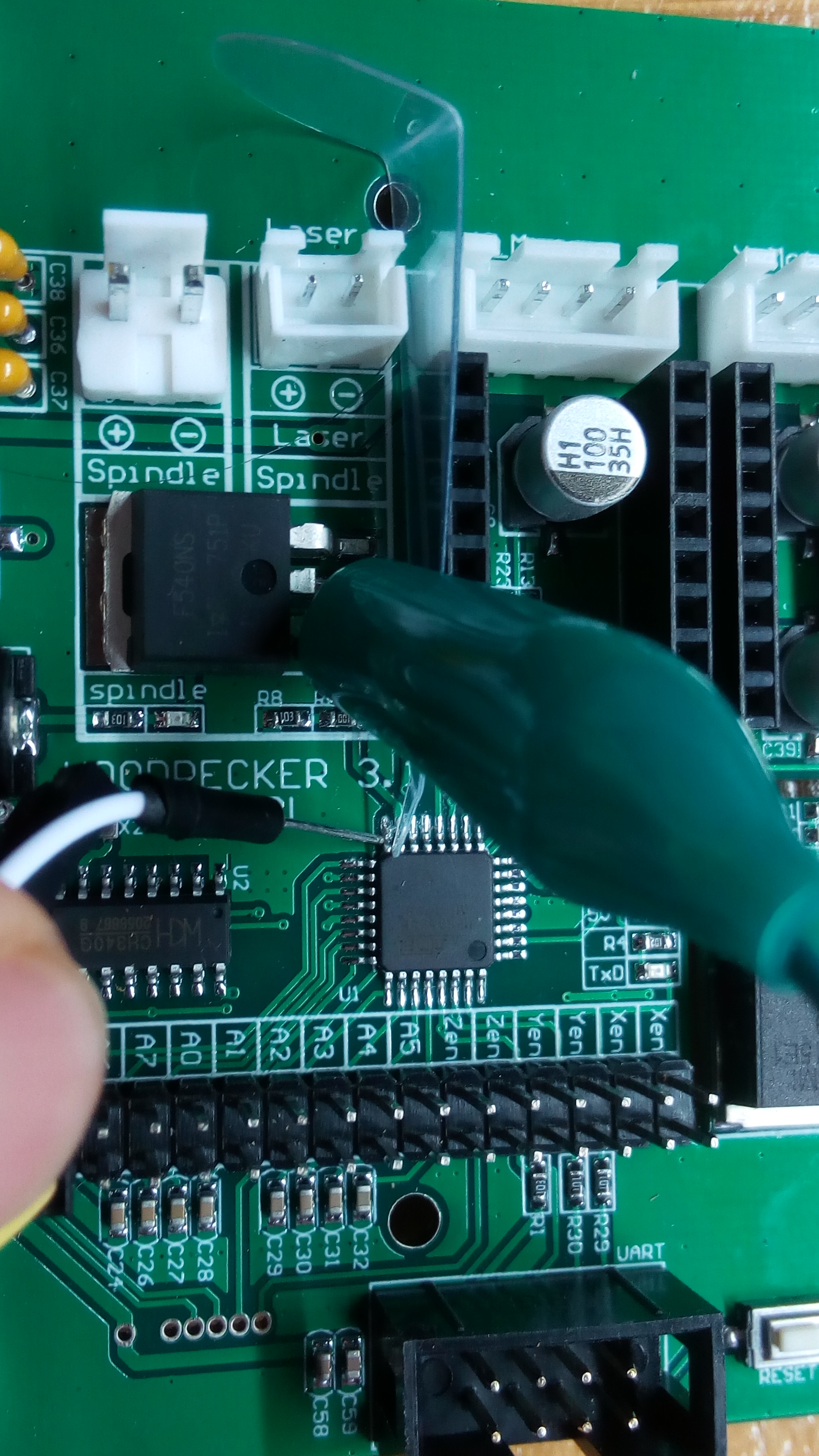

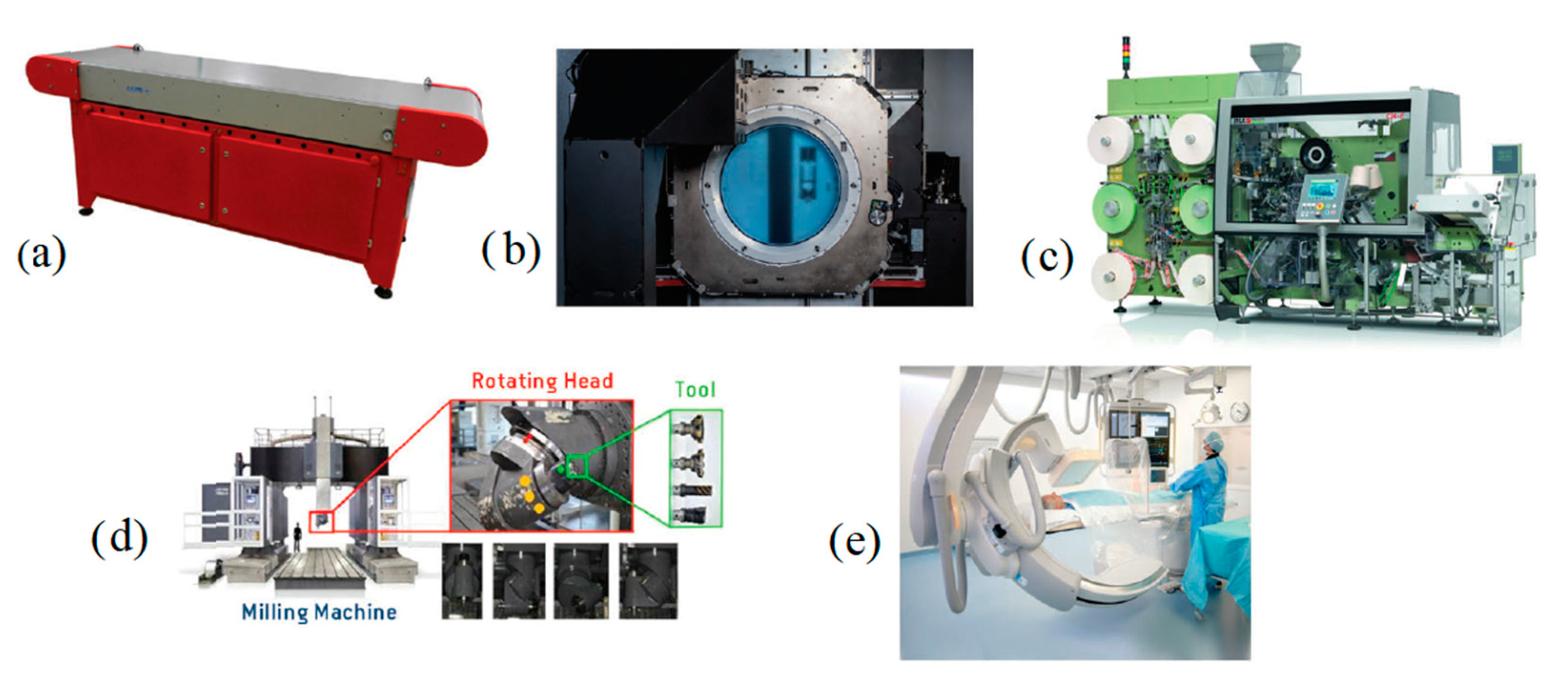

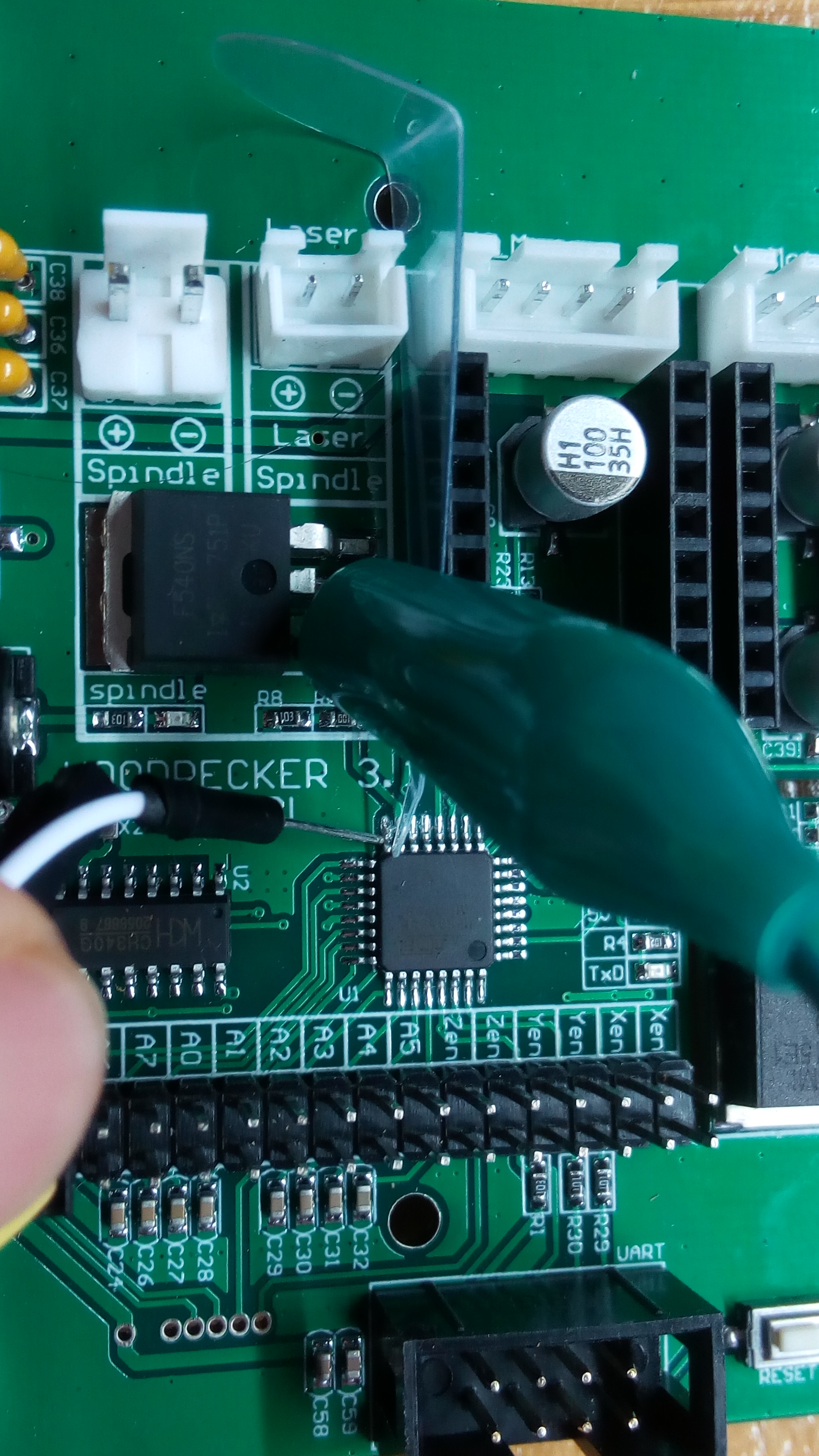

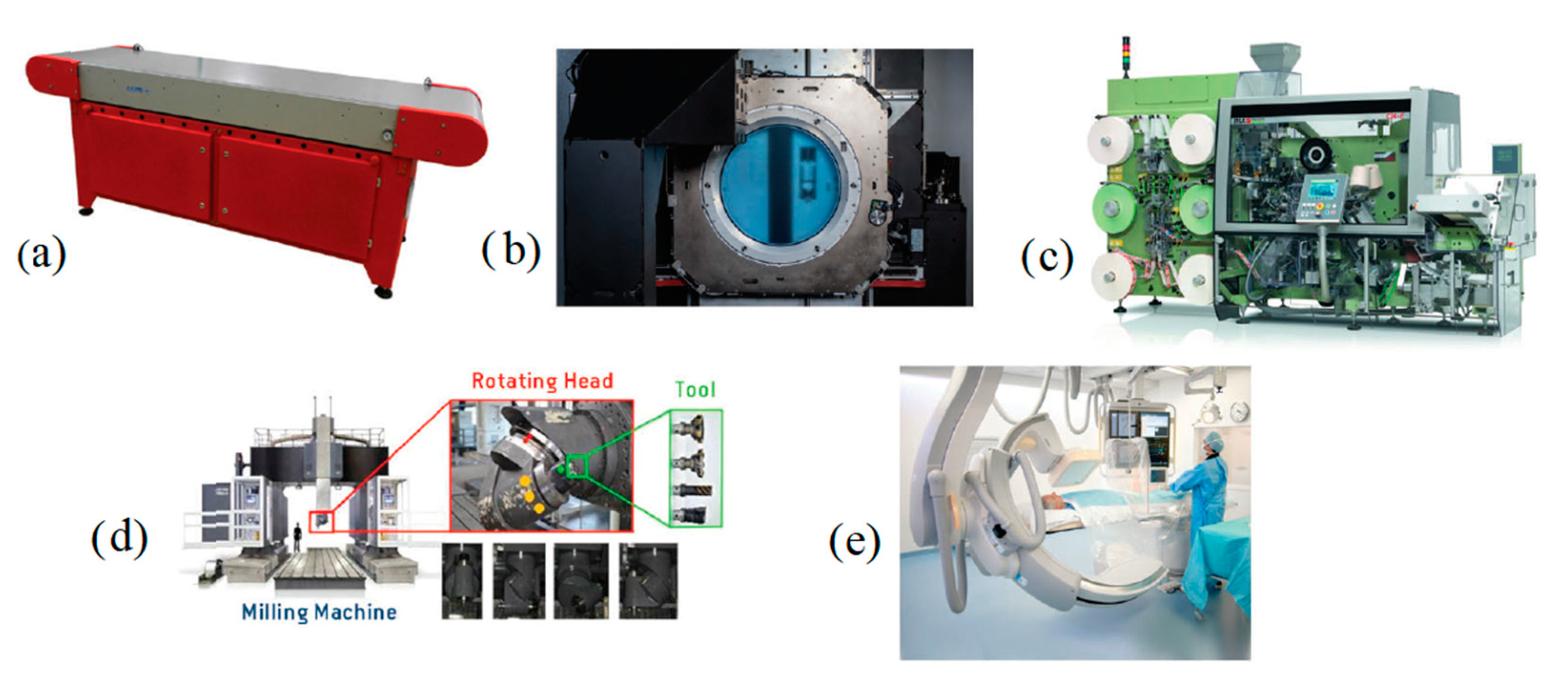

(c) Connect all the stepper drivers of a RepRap or CNC milling machine to an Arduino-based controller (such as a standard RepRap Motherboard 1.2). In principle the software should not be able to tell the difference between (b) and (a), and it should produce the same plastic parts, so in principle the rest of this page describes how to do that, but I don't know anyone that has successfully made good parts this way. (b) Use some other RepStrap or a standard RepRap, and instead of hooking up the stepper drivers to an Arduino-based controller running the RepRap firmware, connect the drivers to the parallel port of a PC running EMC. The rest of this EMCRepRap page describes how to do that. This can be used as a RepStrap to print out all the parts for Darwin or Mendel or Huxley. Let EMC continue to control all the motors through the parallel port, and the extruder through a USB port (or perhaps a spare pin on the parallel port). (a) Use a CNC milling machine hooked up to the parallel port of a PC running EMC, and attach a plastic extruder to the spindle.

There are (at least) 3 ways people combine the excellent EMC software with RepRap technology: A collection of tools intended to RepStrap an EMC controlled CNC Mill or Router.

0 kommentar(er)

0 kommentar(er)